Thermal Insulation Materials: Keeping Buildings Cool and Energy Bills Low

|

| Thermal Insulation Materials |

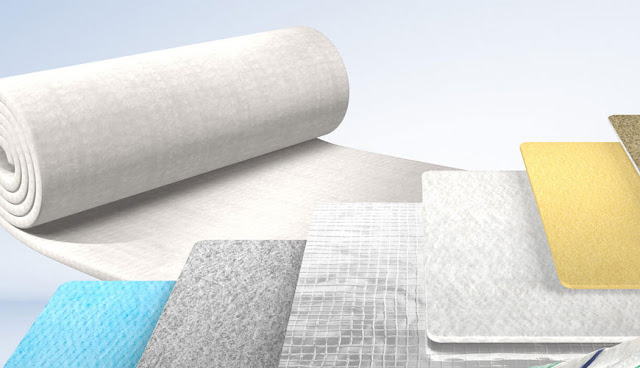

Types of Thermal Insulation Materials

There are various types of materials that are used for thermal insulation

purposes in construction and other industrial applications. Each material has

its own pros and cons depending on the requirement.

Glass Wool

Glass wool or fiberglass is one of the most commonly used thermal insulation

materials. It is made from fine fibers of glass and is available in the form of

batts, boards and loose-fill. Glass wool provides excellent insulation against

heat and sound. It is resistant to moisture, rot and mildew. However, it is not

suitable for exterior applications where there is a risk of water damage.

Mineral Wool

Mineral wool is another synthetic fiber Thermal

Insulation Materials made from molten slag or rock. It has temperature

resistance up to 1200°F. Mineral wool provides effective insulation against

heat, cold, moisture, mold, mildew and corrosion. It has good fire resistance

properties as well. Common types include slag wool and rock wool. Mineral wool

emits some smoke in case of fire but is self-extinguishing.

Polystyrene

Polystyrene comes as extruded polystyrene (XPS) and expanded polystyrene

(EPS) foam insulation boards. It has high resistance to water vapor and

moisture. Polystyrene is lightweight, easy to install and affordable. However,

it is not suitable for applications exposed to direct heat or sunlight as it may

degrade over time. It also has slight smoke emission during fire.

Polyisocyanurate

Polyisocyanurate or polyiso is a rigid foam insulation material with high

insulation efficiency. It has greater thickness for the same thermal resistance

compared to other materials. Polyiso has excellent moisture and aging

resistance. It delivers long term insulation in various climatic conditions and

is commonly used in commercial roofing systems. However, it has a higher cost

compared to other materials.

Cellulose Insulation

Cellulose insulation is made from recycled paper products and provides good

fire resistance. It is easier to install and biodegradable. However, it may

settle over time reducing its insulation properties. Cellulose also absorbs

moisture easily if exposed to wet conditions. Proper installation is important

for long term performance.

Applications of Thermal Insulation

Materials

Thermal insulation materials find wide usage in various construction and

industrial applications based on their individual properties and installation

requirements. Some key areas include:

Wall insulation - Glass wool,

mineral wool, polystyrene boards or blown cellulose are commonly used.

Attic/roof insulation - Glass wool,

cellulose or polyiso boards provide effective insulation in attic floor and

roof applications.

Industrial piping and equipment -

Mineral wool and calcium silicate boards provide corrosion resistant

insulation.

HVAC ducts - Fiberglass wrap or

flexible elastomeric foam insulate ductwork.

Refrigeration equipment - CFC-free

polystyrene or polyurethane foams are often used.

Cold storage - Polyurethane and

polyisocyanurate boards deliver high performance in freezers and cold rooms.

Proper selection, installation and maintenance are important for thermal

insulation materials to deliver their full insulation benefits over the design

life of the structure or equipment. Regular inspection also helps in improving

building energy efficiency. Overall, advancements in material science are

leading to more sustainable and high performance insulation solutions.

Get

more insights on Thermal

Insulation Materials

Comments

Post a Comment